Genesis

Genesis Printable Technical Data Sheet

What is Genesis?

Genesis is the world’s only pure synthetic ceramic metal treatment proven to substantially decrease friction and reduce damaging harmonics and wear in the engine and transmission, in comparison with operation on oil alone. Genesis utilizes ceramic technology “SiC” to form a micro-ceramic seal on all metal parts within your engine, preventing the formation of performance degrading sludge and abrasive carbons. Genesis will restore lost power to your equipment and give you peace of mind.

Genesis utilizes a Ceramic Lubrication Catalyst, which is carried by the oil and is not a normal oil additive. It is also not a replacement for your oil. Genesis is a one-time advanced metal treatment that protects metal parts within your engine, transmission, gearbox and anywhere there is a need for surface enhancement and protection.

Genesis is designed to be used on any rigid or semi-rigid surface subjected to drag, sliding, rotating or oscillating harmonic friction. It is a combination of a unique ceramic resin and lubricating solids and works well in all applications, but is best at high temperatures, high loads and high speeds.

Genesis is formulated to provide an approximate cured film thickness of 6 microns or less of ceramic coating within the valleys of the metal surface. On the asperities (peaks) of the metal surface, it lays a film less than 1-micron, which will not alter factory tolerances or specifications.

How does Genesis work?

Genesis nano-molecules will bind with carbon chains within the metal sub-surface. Once fully cured, it yields a glass smooth sealed surface, eliminating surface flaws within the metals mating surfaces.

The surface boundary layers formed by Genesis have a sub-micronic molecular structure with characteristics that ensure extremely low levels of boundary friction between the surfaces.

Genesis is formulated with a “Surface Tension Modifier” that will reduce temperature, pressure, and friction between moving surfaces, minimizing boundary friction and wear. When the temperature is altered up or down and/or the pressure or friction is increased, Genesis activates a succession of chemical reactions with carbon acids and H2O to reduce the surface tension.

What Genesis Does in Equipment:

Genesis nano-molecules are non-petroleum based ions with an extremely high affinity towards metal surfaces. Genesis molecules are able to penetrate gum and varnish residual buildup on surfaces without the use of solvents. Once Genesis has reached the metal surface after penetrating the varnish buildup, it forms a ceramic shield that protects the metal. Once bonded, the metal surface no longer has the cracks or pores for the gum/varnish particulate to latch onto. Once Genesis is set, it releases the varnish and carbon buildup back into the lubricant stream to be cleaned by the inline and/or bypass filtration system.

Genesis starts to activate at normal equipment temperatures. The higher the temperature, the faster the activation time, the more hours of constant operation, the faster the final results will become apparent.

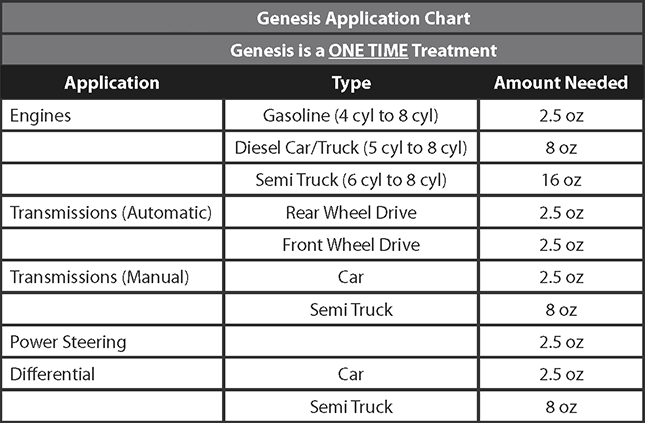

Applications for Genesis:

- Engines

- Transmissions

- Hydraulic systems

- Fuel pumps and injectors

- Drivetrains, trans-axles, hubs and transfer cases

- Air conditioning systems

Does Genesis Affect Your Warranty?

NO! Genesis treats metal only and is a non-hazardous, sub-micronic material. It does not negatively affect the metal surface or any type of seal material.

Genesis Will Significantly Reduce Vibration and Friction in Engines and Equipment

Genesis significantly reduces friction and vibration, thereby providing:

- More power to motorized equipment (increased rpm or improved energy output efficiency at the same rpm)

- Cooler operation in all engines, transmissions, gear boxes, sliding devices and bearing assemblies (as tested it yielded a 450F average reduction in fluid temperatures)

- Longer equipment life

- Significantly longer lubrication (oil) service cycles

- Protection against carbon & lacquer buildup allowing for improved piston sealing

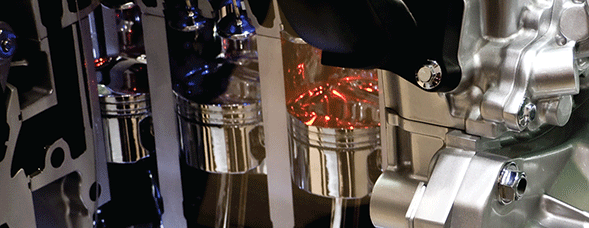

Benefits for Engines

In most cases, Genesis will reduce or eliminate oil burning however, Genesis will not fix physical defects. Many times, parts that appear to be broken are simply heavily coated in lacquers, preventing optimal function. Genesis will remove these lacquers, making the parts work as intended.

Advantages

- Smooths, seals and protects the metal surfaces of bearings, pistons, cams, crankshaft, lifters and all other internal moving metal parts

- Protects engine against friction related heat and wear

- Reduces operating temperatures

- Increases horsepower

- Extends the life of lubricated engine parts

- Reduces oil consumption

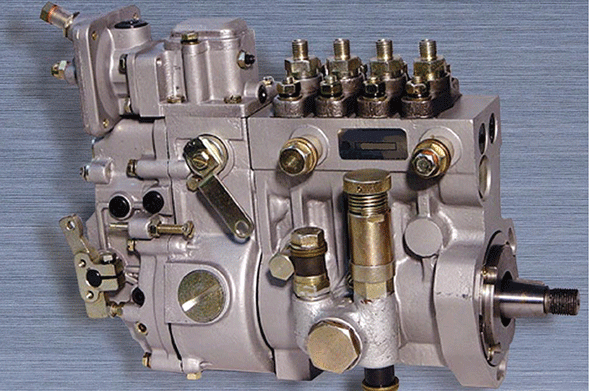

Benefits for Fuel Systems (Genesis for Fuel)

Genesis for Fuel will help alleviate common fuel system issues and help increase the performance of the fuel system. It works as a cleaner, conditioner and metal treatment all-in-one for the fuel system.

Advantages

- Octane booster

- Upper cylinder metal treatment

- Fuel system water remover and cleaner

- Fuel pump conditioner

- Fuel injector cleaner / conditioner

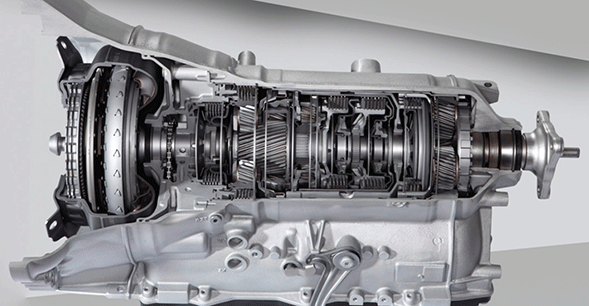

Benefits for Transmissions

One of the biggest enemies of a transmission is heat. The amount of heat present in the system will normally dictate the lifetime of that transmission. When Genesis is added, heat is significantly reduced. Genesis addresses the extreme pressure (EP) areas, such as planetary and worm gear systems, along with bushings, bearings and shafts by penetrating the metal surface and embedding a 6 micron layer ceramic coating. This process drastically reduces the internal friction, leading to a reduction of oil temperature, which will increase the transmissions efficiency and prolong operating life.

Valve Body Operation: In some cases, professional transmission builders have found that Genesis has freed the valve body and maximized performance with no recurrence of sticking or intermittent hang-ups.

Governors: As most builders are aware, there are certain governor systems that have unique tendencies to hang up for no apparent reason. Two reasons these hang-ups occur are contaminants and microscopic spiking of the metal due to electrolytic corrosion of the metal. Genesis will displace contaminants and smooth and seal metal surfaces with ceramic protection, removing electrolytic spikes and preventing their formation.

Advantages

- Lowers operating temperatures

- Frees valve body for maximum performance

- Eliminates governor hang-ups

- Keeps oil passages, orifices and ball checks clean and fully operational

- Extends the service life of the transmission

- Reduces metal particle fallout and debris

- Removes varnish buildup

- Eliminates lock-up chatter in the torque converter

- Ensures proper shifts

- No negative effect on sprag or clutch friction*

- Recommended for automatic and standard transmissions

* Although Genesis reduces friction, it has no negative effect on the sprag or clutch friction necessary for the operation of the transmission. Six years of real world testing, as well as over 20 dynamometer tests, confirm Genesis enhances the transference of horsepower to the road without any ill effects to the transmission.

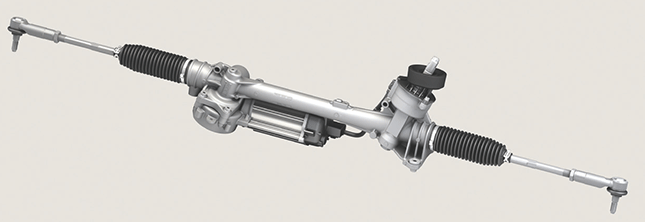

Benefits for Power Steering/Rack Assembly

Advantages

- Quiets noisy power steering pumps

- Reconditions rack piston and cylinders

- Helps return smooth and easy operation to the unit *

* If you are experiencing difficulty with the unit, we recommend the unit be thoroughly flushed prior to the addition of Genesis.

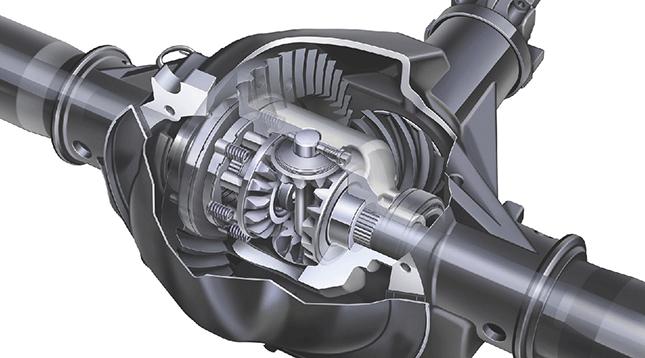

Benefits for Differentials

Advantages

- Treats the metal sub-surfaces of the gears

- Quiets noisy drive trains

- Optimizes performance for more power

- Extends the life of lubricated differential parts

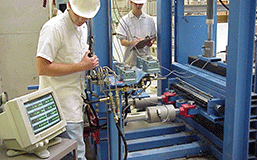

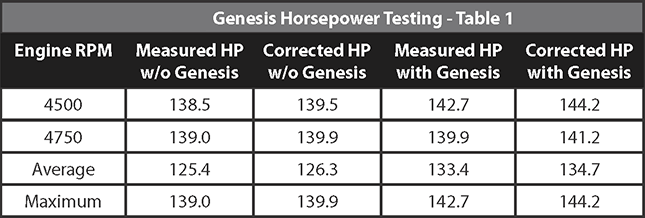

Genesis Improves Horsepower

The improved lubricating properties of lubricants including Genesis oil additive were further demonstrated by comparing the horsepower generated by an automobile engine operating without Genesis added to the lubricant versus the horsepower the horsepower generated by the same automobile engine with Genesis added to the engine lubricant. In each case, the horsepower generated by a 1998 Jeep Grand Cherokee Laredo (“Jeep”) with a 4.0 liter, 6 cylinder engine was measured using a Dynojet Model 248C Dynamometer.

Five quarts of 10W30 petroleum- based motor oil were added to the Jeep, and its horsepower was initially measured prior to addition of Genesis. The automobile was tested from 0 to 5200 RPM with measurements taken at increasing 250 RPM intervals.

The absolute barometric pressure was recorded as 20.92 in. Hg (about 100kPa) with a vapor pressure of 0.61in. Hg (about 2kPa). The intake air temperature was measured at 88.8⁰F (31.6⁰C) and the gear ratio was recorded as 48 RPM/MPH. An SAE correction factor of 1.01 was used to convert the measured horsepower to a corrected horsepower.

A second test was performed on the same automobile by adding 2 ounces of Genesis to the 5 quarts of engine- lubricating oil, resulting in a Genesis concentration of 0.58%.

The measured and corrected horsepower of the Jeep at various engine speeds, operating with lubricant alone versus Genesis added to the lubricant, is detailed below in Table 1.

In comparing the data in Table 1, it can be seen that the corrected horsepower increased by an average of 8.4 horsepower when Genesis was added to the engine lubricant compared with the corresponding tests performed without the additive. Additionally, the maximum horsepower achieved in the tests using Genesis exceeded the maximum horsepower in the tests without the additive by 4.3 horsepower. The test measurements of increased horsepower resulting from use of Genesis supports the conclusion that use of Genesis provides better lubrication of the engine parts.

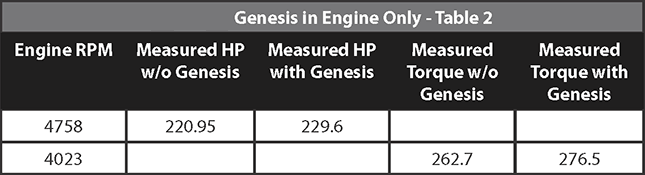

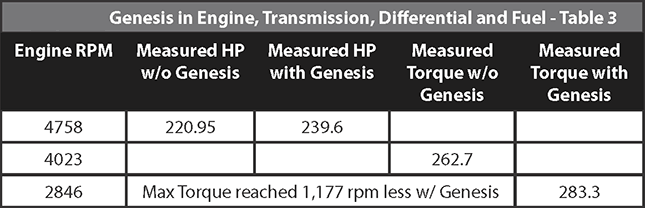

As seen in Table 2, in a second test done on a 2006 Ford F-150 Crew Cab, Genesis was first dyno tested for its benefits in the engine. Table 3 shows the results when it was added to the transmission, differential and the fuel. It can be seen that Genesis increased the horsepower when used in the engine alone by 8.65 horsepower and when added to the transmission, differential and used as a fuel additive, resulted in another 10 horsepower gain for a total gain of 18.65 horsepower! Torque was also increasesd by 20 lbs/ft in testing and the max torque was reached at 1,177 rpm less!

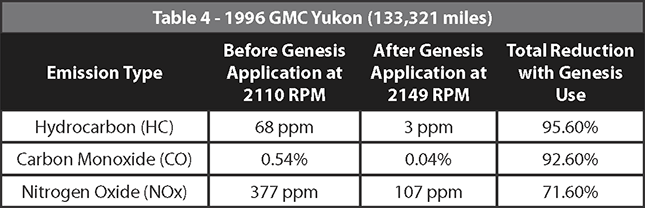

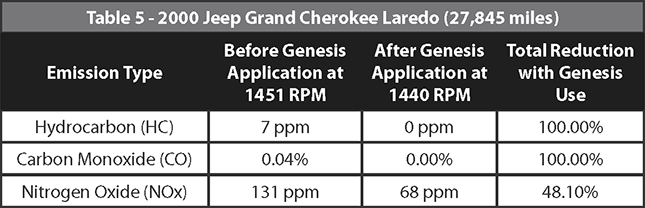

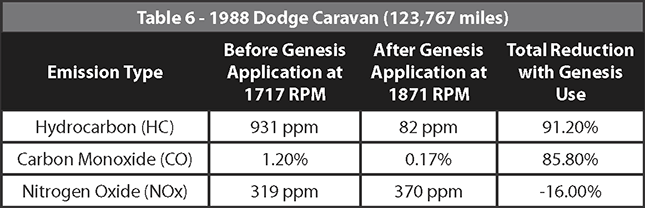

ASM Emission Tests

A comparison of the emissions of automobiles with and without Genesis added to the engine lubricant Penzoil 10W30 was performed using the acceleration simulation mode (ASM) emission test for the State of California. The test results, detailed in Tables 4-6 below, provide the measured exhaust concentrations of hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxide (NOx) gases, which are generally considered harmful. The data in the columns titled “Before Genesis Application” lists the results for the first test in which no Genesis was added to the engine lubricant ( 5 quarts motor oil). The data in the columns titled “After Genesis Application” lists the results of the second tests in which 2 ounces of Genesis were added to the engine lubricant to result in an overall concentration of Genesis in the lubricant of approximately 1.16% by volume.

These test results demonstrate that the use of Genesis significantly reduced the concentration of hydrocarbons and carbon monoxide in each case, and significantly reduced the NOx emissions in all but one of the applications. These results support the conclusion that the use of Genesis improves engine efficiency, which thereby reduces emissions of hydrocarbons, carbon monoxide and NOx gases.

Genesis Before and After Effects on Treated and Untreated Metal

Untreated Metal Genesis Treated Metal

This is a view of what metal surfaces really look like under microscopic , left untreated. right example of Genesis treated

Seal Laboratories report

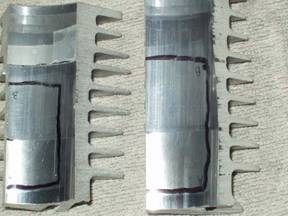

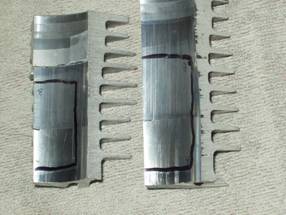

Un-Treated metal Genesis treated metal

Test sheets show the dramatic effects of using Genesis on metal surfaces of a gasoline engine. See test data below.

SEAL Laboratories at 250 N. Nash Street in El Segundo, CA 90245 is performing the tests for presence of the additive in/on the surface of the cylinder block halves, rod caps and the outside edge of the compression ring from the piston. The tests was conducted on an EDX (Energy Dispersive X-Ray) scanning microscope.

The cylinder block will be sectioned to yield a 3/4" X 1-1/2" test coupon containing samples of the contact and non-contact surfaces for testing. The rod caps and rings were tested in one (1) spot only due to the small size of the complete sample.

Dimensional Inspection Laboratories is conducting non-destructive dimensional tests on the remaining halves of the cylinder blocks.

These tests consist of a profilometer reading of surface roughness on the contact and non-contact areas of both cylinder bores and a diameter reading on the same surfaces.

In Seal Laboratories report, figure 6:

In the DIL data the consistent diameter growth of 0.0002 inch each cylinder is expected. However, the reduction of the roughness after running the engines is indicative of the additive's ability to coat and protect the contacting surfaces.

The vertical striations (A) are the machine marks from the manufacturing process. The movement of the piston is from left to right (B). Note is taken of the tears and gouges that indicate the end of the piston stroke on the un-protected sample in (A), while this anomaly is not visible on the protected sample (B). This is also substantiated by the appearance of aluminum particles on the un-protected ring figure 26 and not on the protected ring figure 24 .

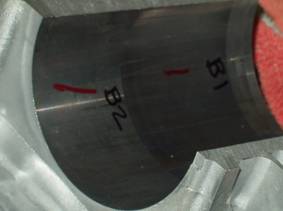

Treated Not treated

This is the section of rings of the test motors (Top) ring No Genesis added ,

Bottom Ring 3 CC of Genesis added to 30 wt Oil. (notice the deposits on the top ring and not on the bottom ring)

On this photo the top ring has been treated, the bottom has not been treated

The next graphs show the surface tension of the cylinder walls before treatment , then the surface tension after treatment with 3 cc of Genesis Metal treatment. See: B-1 treated with Genesis. B-2 Not treated (regular oil) before and after representations as tested.

The engine was run 8 hours with Genesis as represented in fig. B1

Normal Oil With 3 cc. of Genesis

A micron is defined as being 0.00003937 inches or 39.37/1,000,000 of an inch.

|

|

GENESIS TREATED ENGINE |

UN-TREATED ENGINE |

|

SURFACE ROUGHNESS avg. |

.5 micron |

1.0 micron |

|

PEAK ROUGHNESS after STM-3 |

3.5 micron |

4.5 micron |

|

PEAK ROUGHNESS before STM-3 |

21.5 micron |

10.0 micron |

|

DIAMETER after |

2.5620 inches |

2.5620 inches |

|

DIAMETER before |

2.5618 inches |

2.5618 inches |

surface testing

A1 - Cylinder surface using regular oil

B1 - Cylinder surface with 3 ml of Genesis added to regular 30wt oil

Product Application*

Disclaimer: This product must be administered as detailed below or the product will not work as designed and we cannot take responsibility for any failure of performance.

Automotive: Run engine to operating temperature (preferably with old oil but this is not paramount). Administer Genesis dose and immediately drive moderately for 20 to 30 minutes. If driving is not an option (for example: stationary engines, etc.) hold engine at 2,000 RPM’s for 4 minutes and then at idle speed for 60 minutes.

2 Cycle: Administer Genesis dose into the fuel oil mixture tank (running or not), then use for a minimum of 20 to 30 minutes.

Automatic Transmissions: Administer Genesis dose preferably with engine running and drive for 20 to 30 minutes as soon as possible.

Manual Transmissions and Differentials: Administer Genesis dose and drive for 20 to 30 minutes.

*It is preferable to add Genesis while the engine is running, or administer treatment then start engine within 30 seconds; otherwise the treatment will be delayed up to 1,000 miles of driving before it is active. Genesis does not mix with oil, it uses oil as a carrier.

Technical Presentation on Genesis:

{slideboom}[slideboom id=574637]{/slideboom}

Genesis is available in the following convenient sizes:

2.5 oz bottle

8 oz bottle

2 oz bottle (Genesis for Fuel)